Atlas Copco ZR450 Air Compressor

Air compressors are essential machinery for industries ranging from manufacturing to construction. The Atlas ZR450, a high-performance rotary screw air compressor, is designed for heavy-duty applications that require a continuous air supply. However, like all mechanical systems, it is prone to specific issues that can affect its performance. One of the most common problems that operators face is overheating, which can lead to decreased efficiency, increased maintenance costs, and system failures. In this article, we will explore the most common cause of overheating in the Atlas ZR450 and guide how to address and prevent it.

Before diving into the common causes of overheating, it’s important to first understand the key specifications and capabilities of the Atlas ZR450 air compressor:

Air Flow Capacity: 45 m³/min (1590 cfm)

Operating Pressure: Up to 13 bar (190 psi)

Motor Power: 250 kW (335 hp)

Cooling Type: Air-cooled

Oil Tank Capacity: 150 litres (39.6 gallons)

Applications: Heavy industrial operations, construction, mining, and manufacturing

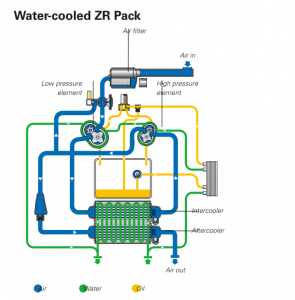

While several factors can contribute to an air compressor's overheating, the most common cause in the Atlas ZR450 case is inadequate ventilation and cooling. The compressor generates a significant amount of heat during operation, and if this heat is not properly dissipated, it can result in overheating.

Why is Cooling So Important?

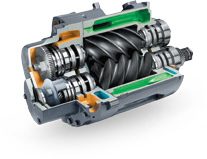

The ZR450, like all rotary screw compressors, relies on oil to lubricate and cool its internal components. The compressor works by compressing air through a series of rotating screws, and this process generates substantial heat. If the cooling system is not functioning effectively, the temperature of the compressor's components can rise beyond safe operating limits.

What Causes Inadequate Ventilation?

- Blocked Air Intake and Exhaust Vents: Over time, dust, dirt, and debris can accumulate around the air intake and exhaust vents, reducing airflow. If these vents are blocked or partially obstructed, the heat generated inside the system cannot be released efficiently.

- Dirty or Clogged Filters: The ZR450 features air filters designed to trap contaminants before they enter the compressor. If these filters are clogged, it can lead to restricted airflow, causing the compressor to overheat.

- Poor Installation Location: The compressor must be installed in an area with sufficient space and airflow. If the unit is placed in a confined space or near walls or obstacles that restrict airflow, the cooling system will not be able to function optimally.

- Faulty or Underperforming Cooling Fans: The cooling fans in the Atlas ZR450 help circulate air around the compressor, ensuring proper heat dissipation. If these fans are malfunctioning or have been damaged, the compressor will overheat.

To prevent overheating caused by inadequate ventilation and cooling, consider the following preventive measures:

1. Regular Cleaning and Maintenance

Ensure that the air intake vents and exhaust systems are free of obstructions. Periodically clean the air filters and replace them as needed to ensure unobstructed airflow. For the Atlas ZR450, it’s essential to inspect the cooling fans regularly to make sure they are in good working condition.

2. Optimal Installation Location

Install the ZR450 in a well-ventilated area that is free of dust and debris. Ensure that there is enough clearance around the unit for airflow, typically at least 1 meter (3 feet) of space on all sides. This ensures that the cooling system can operate effectively.

3. Monitoring Operating Conditions

Keep track of the operating temperature of the compressor, especially during peak usage periods. If the temperature rises beyond the recommended range (5°C to 45°C, or 41°F to 113°F), it may indicate that the cooling system is not functioning properly, or the compressor is operating in an environment that is too hot for efficient cooling.

4. Upgrade Cooling System If Needed

In extremely hot environments, it may be necessary to upgrade or supplement the cooling system. For example, external cooling units, like air coolers or heat exchangers, can help reduce the internal temperature of the compressor and prevent overheating.

While inadequate ventilation is the most common cause, other factors can contribute to overheating:

- Low Oil Levels or Oil Contamination: As a rotary screw compressor, the ZR450 relies on oil for lubrication and cooling. Low oil levels or contaminated oil can lead to friction between moving parts, causing excess heat buildup. Always check and replace oil according to the manufacturer’s schedule to avoid this issue.

- Excessive Load: Running the ZR450 beyond its rated capacity for extended periods can lead to overheating. Ensure that the compressor is operating within its rated flow and pressure capacities (45 m³/min and 13 bar). Overloading the system forces it to work harder and generates more heat than the cooling system can handle.

- Faulty Pressure Relief Valve: The pressure relief valve is designed to prevent the compressor from exceeding its maximum pressure. If this valve fails, it can cause the compressor to run under high pressure for longer periods, leading to overheating.

To avoid overheating and ensure optimal performance of the Atlas ZR450, here are the key takeaways:

- Ensure proper ventilation: Install the compressor in a well-ventilated space and keep intake and exhaust vents clear.

- Maintain oil levels and quality: Regularly check oil levels and replace contaminated oil to prevent friction and excessive heat buildup.

- Avoid overloading: Do not exceed the compressor’s rated capacity. Match the system’s specifications with your operational needs.

- Monitor operating temperature: Keep an eye on the compressor’s temperature to detect any potential overheating issues early.

By following these guidelines and performing regular maintenance, you can extend the life of your Atlas ZR450 air compressor and keep it running at peak performance. Overheating is a common issue, but it is also one of the easiest to prevent with proper care and attention.

| 6900052066 | RING-SEAL | 6900-0520-66 |

| 6900052053 | RING-SEAL | 6900-0520-53 |

| 6900041355 | LOCKWASHER | 6900-0413-55 |

| 6900041023 | RING-RETAINING | 6900-0410-23 |

| 6900040831 | RING-RETAINING | 6900-0408-31 |

| 6900018414 | SWITCH | 6900-0184-14 |

| 6900009453 | FLEXIBLE | 6900-0094-53 |

| 6900009300 | GASKET | 6900-0093-00 |

| 6900009212 | PACKING | 6900-0092-12 |

| 6653133100 | GASKET | 6653-1331-00 |

| 6275623800 | FAN SUPPORT 80 TO 15 | 6275-6238-00 |

| 6275623301 | TOP PANEL RLR 150 | 6275-6233-01 |

| 6275623201 | TOP PANEL RLR 125 | 6275-6232-01 |

| 6275623101 | TOP PANEL RLR 100 | 6275-6231-01 |

| 6275623001 | TOP PANEL RLR 80 | 6275-6230-01 |

| 6275621515 | FRONT PANEL NEAR ELE | 6275-6215-15 |

| 6275621319 | SIDE PANEL | 6275-6213-19 |

| 6275621215 | FRONT PANEL | 6275-6212-15 |

| 6275621119 | SIDE PANEL | 6275-6211-19 |

| 6275614619 | PANEL TOP ADDITIONAL | 6275-6146-19 |

| 6275614410 | MOTOR ASPIRATION PAN | 6275-6144-10 |

| 6275614310 | MOTOR ASPIRATION PAN | 6275-6143-10 |

| 6275614210 | NOZZLE CSB 15/25 D.1 | 6275-6142-10 |

| 6275613910 | DEFLECTOR COOLER CSB | 6275-6139-10 |

| 6275613610 | COOLER CORNER CSB/RL | 6275-6136-10 |

| 6275613310 | SUPPORT DEFLECTOR CS | 6275-6133-10 |

| 6275613210 | TURBINE INLET PANEL | 6275-6132-10 |

| 6275612819 | PANEL | 6275-6128-19 |

| 6275612719 | PANEL RIGHT TOP CSB | 6275-6127-19 |

| 6275611515 | PANEL | 6275-6115-15 |

| 6275611410 | TURBINE DEFLECTOR CS | 6275-6114-10 |

| 6275611310 | PANEL | 6275-6113-10 |

| 6275611210 | PANEL | 6275-6112-10 |

| 6275607319 | PANEL | 6275-6073-19 |

| 6275607219 | BACK PANEL | 6275-6072-19 |

| 6275607119 | PANEL | 6275-6071-19 |

| 6275607019 | PANEL | 6275-6070-19 |

| 6266312700 | VALVE THERM. | 6266-3127-00 |

| 6266312300 | THERMOSTATIC VALVE 8 | 6266-3123-00 |

| 6266308000 | PRESSURE SWITCH, 1/4 | 6266-3080-00 |

| 6266307900 | REGULATOR, CAP-2045S | 6266-3079-00 |

| 6265686200 | PROTECTION FAN QGB | 6265-6862-00 |

| 6265685000 | ASP COOLER AIR | 6265-6850-00 |

| 6265680400 | SUPPORT CENTRAL COOL | 6265-6804-00 |

| 6265680300 | SUPPORT SIDE COOLER | 6265-6803-00 |

| 6265677200 | ETANCHEITE ARMOIRE E | 6265-6772-00 |

| 6265673400 | EQUERRE FIXATION TUY | 6265-6734-00 |

| 6265673000 | ENSEMBLE ARMOIRE ELE | 6265-6730-00 |

| 6265672300 | BRAS SUPPORT TURBINE | 6265-6723-00 |

| 6265671600 | SUPPORT RADIATEUR RL | 6265-6716-00 |

Post time: Jan-15-2025