Atlas Copco ZR75VSD Air Compressor

In industries where compressed air quality is critical, having a reliable and efficient air compressor is paramount. Oil-free air compressors are becoming increasingly popular due to their ability to provide clean, contaminant-free air without the need for lubricating oil. One standout model in this category is the Atlas Copco ZR75 VSD. This advanced oil-free air compressor not only ensures high-quality, pure air but also provides energy-efficient performance and exceptional reliability.

Why Choose an Oil-Free Air Compressor?

Oil-free air compressors are designed to provide compressed air without the risk of oil contamination. In many industries, such as pharmaceuticals, food and beverage production, and electronics manufacturing, even a tiny amount of oil in the air can cause contamination and damage to products. Oil-free compressors are ideal for these applications, offering peace of mind that the air produced is 100% pure. The Atlas Copco ZR75 VSD is a prime example of this technology in action, combining cutting-edge features with high performance and efficiency.

Here are the key technical specifications of the Atlas Copco ZR75 VSD oil-free air compressor:

- Air Delivery (Capacity): 75 kW (100 hp)

- Free Air Delivery (FAD): Ranges from 13.5 to 22.5 m³/min, depending on the model and operating conditions.

- Maximum Working Pressure: 7 bar (101 psi), with options for higher pressures.

- Noise Level: 65 dB(A), providing quiet operation.

- Cooling Type: Air-cooled, making it suitable for a variety of industrial applications.

- Motor Power: 75 kW (100 hp)

- Compressor Technology: Oil-free screw technology with Variable Speed Drive (VSD).

- Dimensions (L x W x H): 2800 x 1060 x 1700 mm. Its compact design makes it easy to install.

- Weight: Approximately 1700 kg (depends on configuration).

- Controller: Smart Air Control system with advanced remote monitoring capabilities for efficient operation.

- Environmental Impact: Reduced oil consumption and disposal, contributing to a cleaner environment.

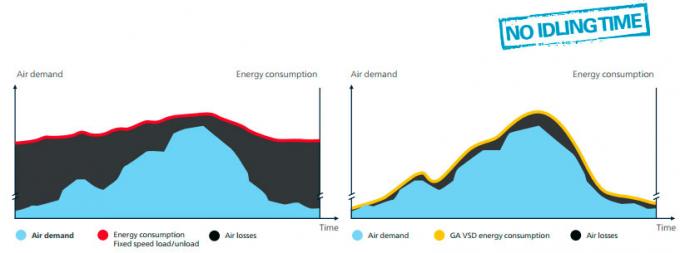

Over 80% of the total lifecycle cost of a compressor is associated with the energy it consumes. Compressed air generation can account for up to 40% of a facility's overall electricity costs. To address these energy expenses, Atlas Copco was a pioneer in introducing Variable Speed Drive (VSD) technology to the compressed air industry. The implementation of VSD technology not only results in significant energy savings but also contributes to environmental protection for future generations. With ongoing investments in the development and improvement of this technology, Atlas Copco now offers the most comprehensive range of integrated VSD compressors available in the market.

- By utilizing a wide turndown range, energy savings of up to 35% can be achieved during fluctuations in production demand.

- The integrated Elektronikon Touch controller ensures optimal performance by managing both the motor speed and the high-efficiency frequency inverter.

- During standard operation, there is no energy wasted due to idle times or blow-off losses.

- Thanks to the advanced VSD motor, the compressor can start and stop at full system pressure without the need to unload.

- Peak current charges during startup are eliminated, contributing to a reduction in overall operational costs.

- The system also reduces leakage by maintaining a lower system pressure.

- Additionally, the compressor is fully compliant with EMC (Electromagnetic Compatibility) directives (2004/108/EG).

The Atlas Copco ZR75 VSD is an advanced oil-free air compressor that utilizes oil-free screw technology to produce clean, high-quality compressed air. Let’s take a closer look at its key features:

- Oil-Free Technology: The ZR75 VSD utilizes a dry screw technology, which eliminates the need for oil in the compression process. This ensures that the air is free from contaminants, making it ideal for sensitive applications. The compressor is built to meet strict standards for air purity, ensuring that no oil mist or particles are present in the compressed air supply.

- Variable Speed Drive (VSD): One of the standout features of the ZR75 VSD is its Variable Speed Drive (VSD). This technology allows the compressor to adjust its speed in real time based on demand. This means that the compressor uses only the amount of energy necessary to meet the air demand, leading to significant energy savings. On average, the ZR75 VSD can reduce energy consumption by up to 35% compared to traditional fixed-speed compressors.

- High Efficiency: The ZR75 VSD is designed to deliver maximum efficiency. Its oil-free design reduces maintenance needs and energy consumption, ensuring long-term cost savings. Additionally, the compressor’s VSD system optimizes its power usage, making it one of the most energy-efficient models available.

- Reliable Performance: The Atlas Copco ZR75 VSD is built for durability and reliability. With its robust components and oil-free design, this compressor offers continuous, reliable performance even in demanding industrial environments. The lack of oil reduces wear and tear, extending the lifespan of the machine and reducing the machine's lifespan.

- Quiet Operation: The ZR75 VSD operates with a noise level of just 65 dB(A), making it one of the quieter compressors in its class. This is particularly beneficial in environments where noise reduction is essential, such as hospitals, laboratories, or indoor manufacturing plants. Quiet operation contributes to a more comfortable and productive working environment.

- Compact and Space-Efficient: Despite its impressive performance capabilities, the ZR75 VSD is designed with a compact footprint, making it easy to install in tight spaces. Its space-saving design allows for easy integration into existing systems and is ideal for businesses with limited floor space.

Here are the key technical specifications of the Atlas Copco ZR75 VSD oil-free air compressor:

- Air Delivery (Capacity): 75 kW (100 hp)

- Free Air Delivery (FAD): Ranges from 13.5 to 22.5 m³/min, depending on the model and operating conditions.

- Maximum Working Pressure: 7 bar (101 psi), with options for higher pressures.

- Noise Level: 65 dB(A), providing quiet operation.

- Cooling Type: Air-cooled, making it suitable for a variety of industrial applications.

- Motor Power: 75 kW (100 hp)

- Compressor Technology: Oil-free screw technology with Variable Speed Drive (VSD).

- Dimensions (L x W x H): 2800 x 1060 x 1700 mm, compact design for easy installation.

- Weight: Approximately 1700 kg (depends on configuration).

- Controller: Smart Air Control system with advanced remote monitoring capabilities for efficient operation.

- Environmental Impact: Reduced oil consumption and disposal, contributing to a cleaner environment.

- Clean Air for Sensitive Applications: The ZR75 VSD ensures 100% oil-free air, making it ideal for industries that require pure air for manufacturing or processing. This is crucial for industries like pharmaceuticals, electronics, and food production, where air quality cannot be compromised.

- Energy Efficiency: With its Variable Speed Drive (VSD) technology, the ZR75 VSD delivers significant energy savings. The compressor automatically adjusts its speed to match air demand, eliminating wasteful energy consumption and providing lower operating costs.

- Lower Maintenance Costs: The ZR75 VSD is designed to be low maintenance due to its oil-free operation. Without the need for oil changes, oil filters, or oil separators, maintenance costs are significantly reduced. Its durable components also minimize the likelihood of breakdowns, lowering the overall cost of ownership.

- Reduced Environmental Impact: The oil-free design reduces the environmental impact by eliminating oil disposal. As a result, the ZR75 VSD is an eco-friendly option that meets strict environmental standards and helps reduce the overall carbon footprint of a facility.

- Quieter Operation: The ZR75 VSD operates at a relatively low noise level of 65 dB(A), making it an excellent choice for noise-sensitive environments. Whether in a hospital, office, or research facility, the quieter operation ensures a more comfortable environment for workers and patients alike.

- Space-Saving Design: Despite its high performance, the ZR75 VSD has a compact footprint, making it easy to fit into tight spaces and integrate into existing systems. This is particularly important for facilities with limited floor space or where space optimization is key.

| 2912437205 | PAK QAS300 500H | 2912-4372-05 |

| 2912437007 | PAK QAS250 2000H | 2912-4370-07 |

| 2912436907 | PAK QAS200 2000H | 2912-4369-07 |

| 2912436806 | PAK QAS200/250 1000H | 2912-4368-06 |

| 2912436705 | PAK QAS200/250 500H | 2912-4367-05 |

| 2912436507 | PAK QAS150 2000H | 2912-4365-07 |

| 2912436406 | PAK QAS150 1000H | 2912-4364-06 |

| 2912436305 | PAK QAS150 500H | 2912-4363-05 |

| 2912436106 | PAK MD 1000H | 2912-4361-06 |

| 2912436006 | PAK MD 1000H | 2912-4360-06 |

| 2912435906 | PAK MD 1000H | 2912-4359-06 |

| 2912435806 | PAK MD 1000H | 2912-4358-06 |

| 2912435805 | PAK | 2912-4358-05 |

| 2912435706 | PAK MD 1000H | 2912-4357-06 |

| 2912435606 | PAK MD 1000H | 2912-4356-06 |

| 2912435605 | PAK MD 400H | 2912-4356-05 |

| 2912435306 | PAK 1000H | 2912-4353-06 |

| 2912435206 | PAK 1000H LP CA | 2912-4352-06 |

| 2912435205 | PAK 250H | 2912-4352-05 |

| 2912435106 | PAK 1000H | 2912-4351-06 |

| 2912435006 | PAK 1000H | 2912-4350-06 |

| 2912435005 | PAK 500H | 2912-4350-05 |

| 2912434806 | PAK | 2912-4348-06 |

| 2912434106 | PAK QA 115-165 1000H | 2912-4341-06 |

| 2912434005 | PAK QA 115-165 500HR | 2912-4340-05 |

| 2912433904 | PAK QA 115-165 50HR | 2912-4339-04 |

| 2912433806 | SERV.PAK1000H XAS186 | 2912-4338-06 |

| 2912433706 | SERV.PAK1000H XAS186 | 2912-4337-06 |

| 2912433607 | SERVICE PAK PTE 2000 | 2912-4336-07 |

| 2912433506 | PAK QA 75-105 1000HR | 2912-4335-06 |

| 2912433405 | PAK QA75-105 500HR | 2912-4334-05 |

| 2912433304 | PAK QA75-105 50HR | 2912-4333-04 |

| 2912433206 | PAK 1000H XAHS186DD | 2912-4332-06 |

| 2912433105 | PAK 500H XAHS186DD | 2912-4331-05 |

| 2912432906 | PAK QA 50-60 1000HR | 2912-4329-06 |

| 2912432805 | PAK QA 50-60 500HR | 2912-4328-05 |

| 2912432406 | KIT-SERVICE | 2912-4324-06 |

| 2912432305 | KIT-SERVICE | 2912-4323-05 |

| 2912431806 | PAK QA 27-44 1000HR | 2912-4318-06 |

| 2912431706 | PAK QA 15-22 1000HR | 2912-4317-06 |

| 2912431605 | PAK QA 15-44 500HR | 2912-4316-05 |

| 2912431504 | PAK QA 15-44 50HR | 2912-4315-04 |

| 2912430906 | SERV PAK | 2912-4309-06 |

| 2912430706 | PAK 1000H XATS156DD | 2912-4307-06 |

| 2912430605 | PAK 500H XATS156DD | 2912-4306-05 |

| 2912430007 | KIT 2000 HR GD | 2912-4300-07 |

| 2912429904 | INITIAL PAK | 2912-4299-04 |

| 2912429106 | KIT-SERVICE | 2912-4291-06 |

| 2912429005 | KIT-SERVICE | 2912-4290-05 |

| 2912428906 | KIT 1000 HR GD | 2912-4289-06 |

Post time: Feb-18-2025