Atlas Copco ZS4 series screw air compressors.

Welcome to the user manual for the Atlas Copco ZS4 series screw air compressors. The ZS4 is a high-performance, oil-free screw compressor that provides reliable, energy-efficient air compression solutions for various industries, including food and beverage, pharmaceuticals, textiles, and more. This guide covers the usage instructions, key specifications, and maintenance procedures to ensure the longevity and optimal performance of your ZS4 air compressor.

Company Overview:

We are an Atlas Copco Authorized Distributor, recognized as a top-tier exporter and supplier of Atlas Copco products. With years of experience in providing high-quality air solutions, we offer a comprehensive range of products, including but not limited to:

- ZS4 – Oil-Free Screw Air Compressor

- GA132 – Air Compressor

- GA75 – Air Compressor

- G4FF – Oil-Free Air Compressor

- ZT37VSD – Oil-Free Screw Compressor with VSD

- Comprehensive Atlas Copco Maintenance Kits – Genuine parts, including filters, hoses, valves, and seals.

Our commitment to excellent customer service and product quality makes us a trusted partner for businesses worldwide.

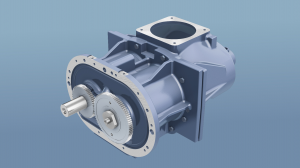

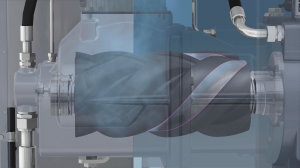

The Atlas Copco ZS4 is designed to provide high-quality, oil-free compressed air with minimal operational cost. It uses a unique screw element design to ensure maximum reliability and efficiency. The ZS4 is engineered to meet the highest industry standards for air purity and energy efficiency.

Key Specifications of ZS4:

- Model: ZS4

- Type: Oil-Free Screw Air Compressor

- Pressure Range: 7.5 – 10 bar (adjustable)

- Free Air Delivery (FAD):

- 7.5 bar: 13.5 m³/min

- 8.0 bar: 12.9 m³/min

- 8.5 bar: 12.3 m³/min

- 10 bar: 11.5 m³/min

- Motor Power: 37 kW (50 hp)

- Cooling: Air-cooled

- Sound Level: 68 dB(A) at 1m

- Dimensions:

- Length: 2000 mm

- Width: 1200 mm

- Height: 1400 mm

- Weight: Approx. 1200 kg

- Compressor Element: Oil-free, durable screw design

- Control System: Elektronikon® Mk5 controller for easy monitoring and control

- Air Quality: ISO 8573-1 Class 0 (oil-free air)

1. Efficient, clean and reliable compression

Certified oil-free compression technology (Class 0 certified)

• Durably-coated rotors ensure optimal operational clearances

• Perfectly sized and timed inlet- and outlet port and rotor profile result in the lowest specific power consumption

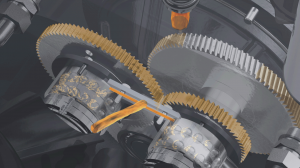

• Tuned cool oil injection to bearings and gears maximizing the lifetime

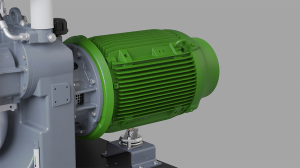

2. High-efficient motor

• IE3 & Nema premium efficient motor

• TEFC for operation in the harshest environmental conditions

- Installation:

- Place the compressor on a stable, flat surface.

- Ensure that there is sufficient space around the compressor for ventilation (at least 1 meter on each side).

- Connect the air intake and outlet pipes securely, ensuring that there are no leaks.

- Ensure that the power supply matches the specifications indicated on the unit's nameplate (380V, 50Hz, 3-phase power).

- It is highly recommended that an air dryer and filtration system be installed downstream to ensure the quality of the compressed air.

- Start-Up:

- Turn on the compressor by pressing the power button on the Elektronikon® Mk5 controller.

- The controller will initiate a startup sequence, checking the system for any faults before beginning operation.

- Monitor the pressure, temperature, and system status through the controller’s display panel.

- Operation:

- Set the required operating pressure using the Elektronikon® controller.

- The ZS4 is designed to adjust its output to meet your demand automatically, ensuring optimal energy efficiency.

- Regularly check for abnormal noises, vibrations, or any changes in performance that may indicate maintenance is needed.

Proper maintenance of your ZS4 compressor is essential to keeping it running efficiently and ensuring its longevity. Follow these maintenance steps at the recommended intervals to maintain your unit's performance.

Daily Maintenance:

- Check the Air Intake: Ensure that the air intake filter is clean and free from any blockages.

- Monitor the Pressure: Check the system pressure regularly to ensure it is within the optimal range.

- Inspect the Controller: Verify that the Elektronikon® Mk5 controller is functioning properly and displaying no errors.

Monthly Maintenance:

- Check the Oil-Free Screw Element: Although the ZS4 is an oil-free compressor, it is important to inspect the screw element for any signs of wear or damage.

- Check for Leaks: Inspect all connections for air or oil leaks, including air pipes and valves.

- Clean the Cooling System: To maintain proper heat dissipation, ensure the cooling fins are free from dust or debris.

Quarterly Maintenance:

- Replace the Intake Filters: Replace the air intake filters as per the manufacturer’s recommendation to maintain air quality.

- Check the Belts and Pulleys: Inspect the belts and pulleys for signs of wear and replace them if necessary.

- Clean the Condensate Drain: Ensure the condensate drains are functioning properly to prevent moisture buildup.

Annual Maintenance:

- Service the Controller: Update the Elektronikon® Mk5 software if necessary and check for firmware updates.

- Full System Inspection: Have a certified Atlas Copco technician perform a complete inspection of the compressor, checking internal components, pressure settings, and the general health of the system.

Maintenance Kit Recommendations:

We offer Atlas Copco-approved maintenance kits to help you keep your ZS4 running smoothly. These kits include filters, lubricants, hoses, seals, and other critical components to ensure the highest performance.

The Atlas Copco ZS4 air compressor is designed for those who demand reliability, performance, and energy efficiency. By following the operational guidelines and scheduled maintenance procedures outlined above, you can maximize your compressor's lifespan and efficiency.

As an Atlas Copco Authorized Supplier, we are proud to offer the ZS4, along with other high-quality products, such as GA132, GA75, G4FF, ZT37VSD, and a wide range of maintenance kits. Our team is here to provide expert advice and exceptional service to meet your industrial needs.

For more information or assistance, please contact us directly. We're happy to help you find the best air solutions for your business.

Thank you for choosing Atlas Copco!

| 2205190875 | GEAR PINION | 2205-1908-75 |

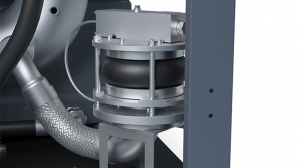

| 2205190900 | THERMOSTATIC VALVE | 2205-1909-00 |

| 2205190913 | PIPE-FILME COMPRESSOR | 2205-1909-13 |

| 2205190920 | BAFFLE ASSEMBLY | 2205-1909-20 |

| 2205190921 | FAN COVER | 2205-1909-21 |

| 2205190931 | SEALING WASHER | 2205-1909-31 |

| 2205190932 | SEALING WASHER | 2205-1909-32 |

| 2205190933 | SEALING WASHER | 2205-1909-33 |

| 2205190940 | PIPE FITTING | 2205-1909-40 |

| 2205190941 | U-DISCHARGE FLEXIBLE | 2205-1909-41 |

| 2205190943 | HOSE | 2205-1909-43 |

| 2205190944 | OUTLET PIPE | 2205-1909-44 |

| 2205190945 | AIR INLET PIPE | 2205-1909-45 |

| 2205190954 | SEALING WASHER | 2205-1909-54 |

| 2205190957 | SEALING WASHER | 2205-1909-57 |

| 2205190958 | FLEXIBLE OF AIR INLET | 2205-1909-58 |

| 2205190959 | FLEXIBLE OF AIR INLET | 2205-1909-59 |

| 2205190960 | OUTLET PIPE | 2205-1909-60 |

| 2205190961 | SCREW | 2205-1909-61 |

| 2205191000 | PIPE-FILME COMPRESSOR | 2205-1910-00 |

| 2205191001 | FLANGE | 2205-1910-01 |

| 2205191100 | PIPE-FILME COMPRESSOR | 2205-1911-00 |

| 2205191102 | FLANGE | 2205-1911-02 |

| 2205191104 | EXHAUST HOSE | 2205-1911-04 |

| 2205191105 | EXHAUST HOSE | 2205-1911-05 |

| 2205191106 | EXHAUST SYPHON | 2205-1911-06 |

| 2205191107 | AIR OUTLET PIPE | 2205-1911-07 |

| 2205191108 | SEALING WASHER | 2205-1911-08 |

| 2205191110 | PIPE-FILME COMPRESSOR | 2205-1911-10 |

| 2205191121 | AIR OUTLET PIPE | 2205-1911-21 |

| 2205191122 | FLEXIBLE OF AIR INLET | 2205-1911-22 |

| 2205191123 | FLEXIBLE TUBE | 2205-1911-23 |

| 2205191132 | FLANGE | 2205-1911-32 |

| 2205191135 | FLANGE | 2205-1911-35 |

| 2205191136 | RING | 2205-1911-36 |

| 2205191137 | RING | 2205-1911-37 |

| 2205191138 | FLANGE | 2205-1911-38 |

| 2205191150 | FLEXIBLE OF AIR INLET | 2205-1911-50 |

| 2205191151 | RING | 2205-1911-51 |

| 2205191160 | OUTLET PIPE | 2205-1911-60 |

| 2205191161 | RING | 2205-1911-61 |

| 2205191163 | OUTLET PIPE | 2205-1911-63 |

| 2205191166 | SEALING WASHER | 2205-1911-66 |

| 2205191167 | U-DISCHARGE FLEXIBLE | 2205-1911-67 |

| 2205191168 | OUTLET PIPE | 2205-1911-68 |

| 2205191169 | BALL VALVE | 2205-1911-69 |

| 2205191171 | SEALING WASHER | 2205-1911-71 |

| 2205191178 | PIPE-FILME COMPRESSOR | 2205-1911-78 |

| 2205191179 | BOX | 2205-1911-79 |

| 2205191202 | OIL INFALL PIPE | 2205-1912-02 |

Post time: Jan-06-2025