Products

Atlas Copco ZS4 Screw Air Compressor For China Atlas Copco Zs4 Exporter

Air compressor product introduction

Atlas Copco oil-free screw compressor

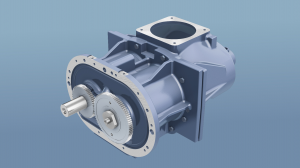

The Atlas Copco ZS4 is a revolutionary oil-free screw blower, designed to provide highly efficient and reliable performance in a variety of industrial applications. Engineered with cutting-edge technology, the ZS4 delivers an exceptional combination of energy savings, environmental benefits, and low maintenance costs. Whether it's for air supply in wastewater treatment plants, pneumatic conveying, or other industrial applications requiring high-quality compressed air, the ZS4 is your ideal solution.

Atlas Copco Zs4 Key Features

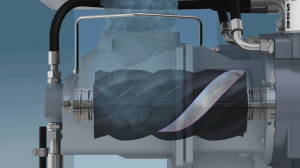

1. Efficient, clean and reliable compression

• Certified oil-free compression technology (Class 0 certified)

• Durably-coated rotors ensure optimal operational clearances

• Perfectly sized and timed inlet- and outlet port and rotor profile

result in the lowest specific power consumption

• Tuned cool oil injection to bearings and gears maximizing the

lifetime

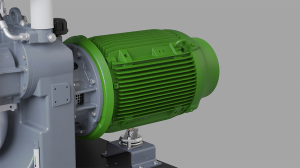

2. High-efficient motor

• IE3 & Nema premium efficient motor

• TEFC for operation in the harshest environmental conditions

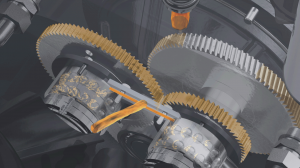

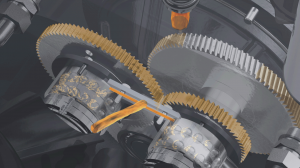

3. Reliability by ensuring cooling and lubrication of bearings and gears

• Integrated oil pump, directly driven with the blower element

• Oil injection nozzles spray the optimal amount of cooled and

filtered oil to each bearing/gear

4. Most efficient transmission, minimum maintenance required!

• Motor-screwblower transmission over a heavy-duty gearbox

• Low maintenance costs, no wearing components such as

belts, pulleys, ...

• A gear transmission is stable over time, ensuring the promised

unit energy level over its full life cycle

5. Advanced touchscreen monitoring system

• User-friendly Elektronikon® Touch

• Advanced connectivity capabilities thanks to sthe ystem process

controller and/or Optimizer 4.0

• Included warning indications, maintenance scheduling and

online visualization of the machine’s condition

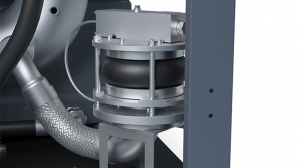

6. Built-in mechanical integrity & protection

• Integrated start-up and safety valve: smooth start-up, ensured

over-pressure protection

• Atlas Copco check-valve design: minimal pressure drop,

ensured operation

• High-efficiency inlet filter (particles up to 3μ at a performance

of 99.9% are filtered)

7. Silent canopy, silent blower

• Inlet baffle silencing with minimum pressure drop and high

sound absorption characteristics

• Sealed canopy panels and doors

• Discharge pulsation damper attenuates dynamic pulsation

levels in the air flow to the minimum

8. Installation flexibility - outdoor variant

• Optional canopy panels for outdoor operation

Why Choose Atlas Copco ZS4?

- Energy Efficiency: Thanks to its state-of-the-art design and optimized components, the ZS4 can help reduce your energy consumption by up to 30% compared to traditional blowers.

- No Oil Contamination: As an oil-free unit, the ZS4 eliminates the risk of oil contamination in your compressed air system, ensuring clean, high-quality air for all applications.

- Low Operating Costs: With fewer components requiring maintenance, no oil changes, and high reliability, the ZS4 offers substantial savings in maintenance and operational costs.

- Sustainability: By reducing energy consumption and eliminating the need for oil, the ZS4 supports your sustainability goals while reducing your environmental footprint.

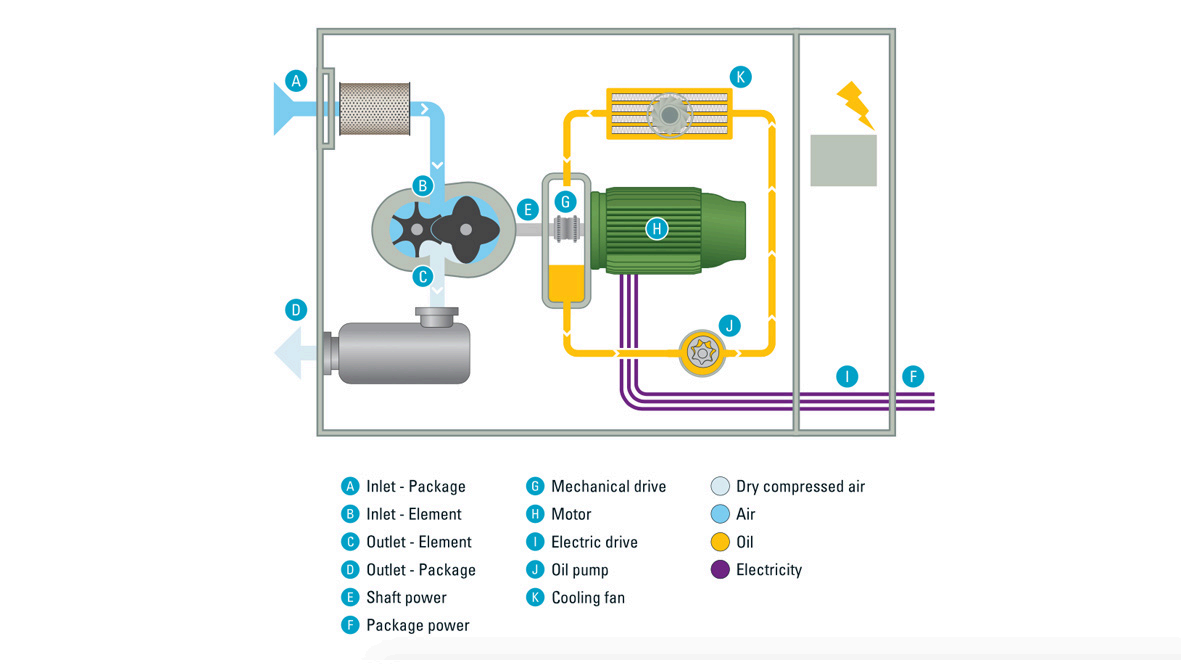

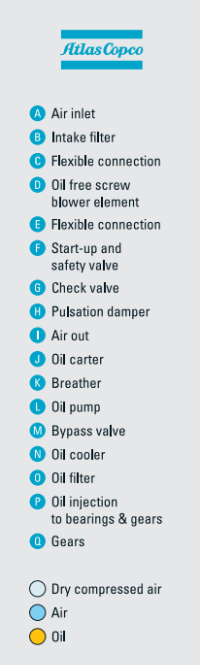

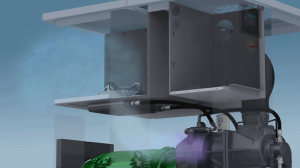

Atlas Copco Flowcharts ZS 4

Process flow

• Air intake with noise attenuating baffle system.

• Air is filtered prior to entering the screwblower element.

• Internal compression in the oil-free screwblower element.

• At start-up, the blow-off valve is 'open' for smooth unit start-up.

That valve closes itself, pushed by the increased air pressure.

• As soon as the blow-off valve is closed, air pressure increases

further, resulting in enough force to push the check-valve open.

• Discharge silencer reduces the pressure pulsation levels to the

minimum.

• Air delivery to the system.

Oil flow

• Oil pump, mounted on screwblower shaft hence directly driven.

• Oil suction from Carter, integrated into the gearbox.

• Bypass valve decides the exact oil flow that is required for bearing

and gear cooling and lubrication.

• That oil first is pumped through the oil cooler.

• Then the cool oil is fine-filtered.

• Filtered cool oil is distributed to individually tuned oil nozzles per

bearing and/or gear in the screwblower element and gearbox.

• Internal drains recover all oil in the carter (in the gearbox).

Cooling flow

• One cooling fan pulls fresh air from the unit back side.

• That fresh air is pushed through the oil cooler, taking away the

heat of the oil.

• In parallel, the motor cooling fan also pulls fresh air from the unit

back side. The motor fan-cowl ensures that air flows over the

motor cooling fins.

• The cubicle is cooled with fresh air taken-in through filters in the

front door.

• Cubicle fans push the hot air out of the cubicle, in the canopy.

• The hot canopy air (oil cooling heat, motor cooling heat and

cubicle heat) can leave the canopy through a roof-top grating. A

noise attenuating baffle is installed.

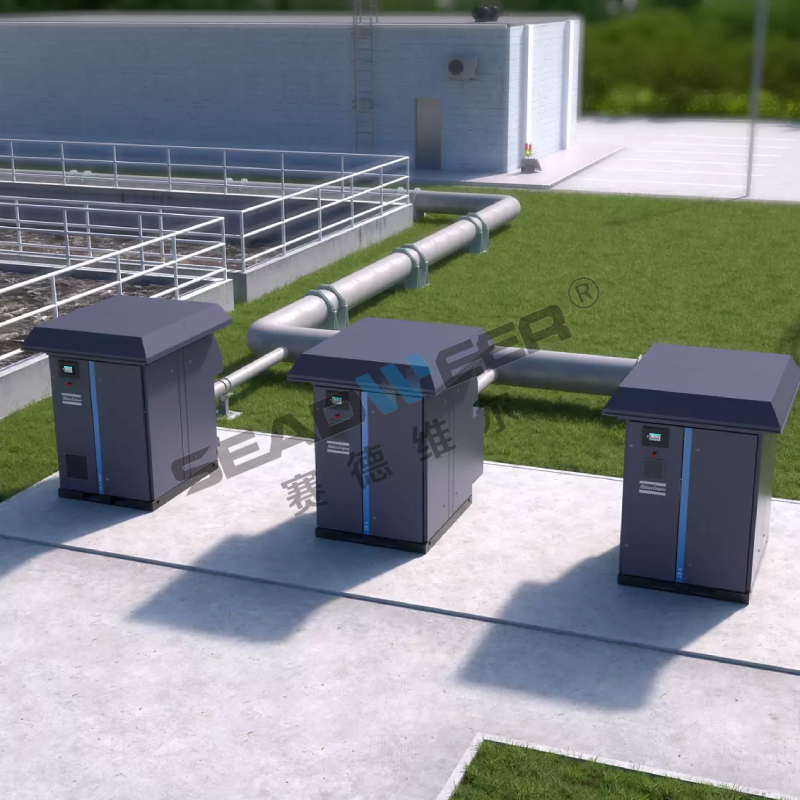

Atlas Copco zs4 application scenarios

- Wastewater Treatment Plants: Ideal for aeration, the ZS4 ensures consistent, oil-free air delivery to meet stringent air quality standards.

- Pneumatic Conveying: Perfect for conveying materials in a variety of industries, from food processing to bulk handling.

- Industrial Air Supply: Suitable for general industrial air supply where oil-free, compressed air is essential for machinery protection and product quality.

- Aquaculture: Provides a reliable source of oxygen for fish farming operations, helping to maintain healthy environments for aquatic life.

| 2012103039 | Oil Stop and Check Valve Kit | 2012103039 |

| 2012103042 | Thermostatic Valve Kit 181F | 2012103042 |

| 2012103037 | Unloader Kit QSI 75-125, QGV 75-125 | 2012103037 |

| 2014503143 | Coupling Element | 2014503143 |

| 1089057470 | Temp. Sensor | 1089057470 |

| 1089070214 | Unloader Solenoid Valve | 1089070214 |

| 2014000891 | E-Stop Button | 2014000891 |

| 2010356647 | Contact Block NC | 2010356647 |

| 2014703682 | Relay, 8 Amp DPDT | 2014703682 |

| 2014703800 | Phase Monitor Relay 200-690V | 2014703800 |

| 1089057554 | Pressure Transducer 0-250 PS | 1089057554 |

| 2013900054 | Check valve ( shaft seal ) | 2013900054 |

| 2014706101 | Temp. Switch 230F | 2014706101 |

| 1627456072 | Minimum Pressure check valve kit | 1627456072 |

| 1627456034 | Thermal Valve Kit | 1627456034 |

| 2013200649 | 2013200649 | |

| 1627423003 | Drive Coupling Element | 1627423003 |

| 2014000891 | E-Stop Button | 2014000891 |

| 2010356647 | Contact Block 1 NC | 2010356647 |

| 2014703800 | Phase Monitor 200-230V | 2014703800 |

| 2012102144 | Phase Monitor 480V | 2012102144 |

| 2014000848 | Transducer, 0-300 PSI, 4-20 MA | 2014000848 |

| 2014000023 | Temp. Sensor ( PLC Control ) | 2014000023 |

| 1089057470 | Temp. Sensor ( Q Control ) | 1089057470 |

| 1089057554 | Pressure Transducer ( Q Control ) | 1089057554 |

| 2014706335 | Solenoid Valve 3 Way | 2014706335 |

| 2014703682 | Relay, 8 Amp 120V DPDT | 2014703682 |

| 2014706101 | Temperature switch 230F | 2014706101 |

| 1627456046 | Thermal Valve kit | 1627456046 |

| 1627413040 | Gasket, Discharge Coupling | 1627413040 |

| 1627423002 | Drive Coupling Element ( QSI370i ) | 1627423002 |

| 1627423003 | Drive Coupling Element ( QSI500i ) | 1627423003 |

| 1089057470 | Temp. Sensor ( Q Control ) | 1089057470 |

| 1089057554 | Pressure Transducer ( Q Control ) | 1089057554 |

| 2014703682 | Relay ( Q Control ) | 2014703682 |

| 2014704306 | Pressure switch ( STD PLC Control ) | 2014704306 |

| 2014706335 | Solenoid Valve 3 way | 2014706335 |

| 2014600200 | 2014600200 | |

| 2012100202 | Inlet Valve Air Motor kit ( QSI500i ) | 2012100202 |

| 2014706101 | Temperature switch 230F | 2014706101 |

| 1627456046 | Thermal Valve kit | 1627456046 |

| 1627413040 | Gasket, Discharge Coupling | 1627413040 |

| 1627423002 | Drive Coupling Element ( QSI370i ) | 1627423002 |

| 1627423003 | Drive Coupling Element ( QSI500i ) | 1627423003 |

| 2014000023 | Temp Probe (Electronic Control) P$ | 2014000023 |

| 2014000848 | Pressure Transducer | 2014000848 |

| 1627441153 | Module Analog (P$) | 1627441153 |

| 2014706335 | Solenoid Valve 3 way | 2014706335 |

| 2014704306 | Pressure Switch (PLC Control) | 2014704306 |

| 2014706093 | Temp Switch 225F ( STD Unit ) | 2014706093 |

Write your message here and send it to us