Products

Atlas Copco Screw air compresssor GA75 For Atlas Copco suppliers

Air compressor product introduction

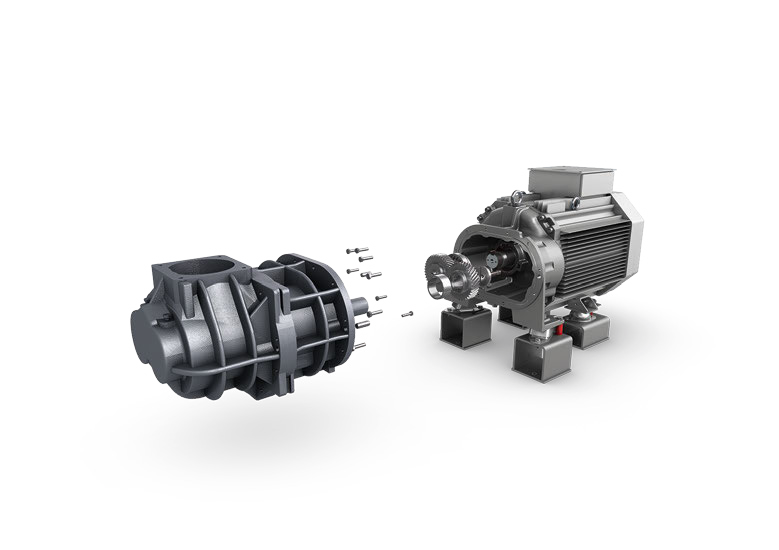

The Atlas Copco GA 75 is a high-performance oil-injected rotary screw air compressor, designed to deliver reliable, efficient, and cost-effective compressed air solutions for a variety of industrial applications. With its robust design and cutting-edge technology, the GA 75 offers optimal performance and energy savings, making it an ideal choice for businesses seeking to enhance productivity and reduce operational costs.

Equipped with advanced features such as an integrated airend, an energy-efficient motor, and a user-friendly controller, the GA 75 ensures seamless operation, reduced maintenance, and long-term durability. Whether operating in manufacturing, automotive, or food processing, the GA 75 provides the dependable air supply you need to keep your business running smoothly.

Atlas Copco GA 75 high reliability and smart energy

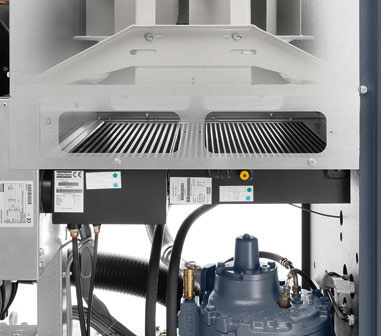

Integrated highly efficient R410A dryer

• Excellence in air quality.

• 50% reduction in energy consumption compared to traditional dryers.

• Zero ozone depletion.

• Incorporates optional UD+ filter according to Class 1.4.2.

Atlas Copco GA 75 Key Features

- High Efficiency: The GA 75 is designed to maximize energy efficiency with a high-performance motor and optimized airend. The result? Reduced energy consumption and lower operational costs, even under demanding conditions.

- Durable and Reliable: Built with quality materials and advanced technology, the GA 75 ensures maximum reliability and a long service life. Its heavy-duty components are engineered to withstand harsh industrial environments.

- Integrated Controller: The Elektronikon® Mk5 controller allows for real-time monitoring and optimization of the compressor’s performance. You can control and track the compressor’s operation remotely, ensuring optimal efficiency and early detection of potential issues.

- Low Maintenance Costs: With fewer moving parts and a smart design, the GA 75 requires minimal maintenance, leading to lower service costs and less downtime.

- Quiet Operation: Designed to operate quietly, the GA 75 ensures a more comfortable working environment with reduced noise levels, making it ideal for workplaces where noise control is a priority.

- Compact and Space-Saving: Its compact design makes the GA 75 easy to install in even the most space-constrained environments, offering flexibility and ease of integration into your existing system.

- Environmental Benefits: The GA 75 is engineered to reduce your carbon footprint, delivering the performance you need while supporting your sustainability goals.

Atlas Copco GA75 Application Scenarios

- Manufacturing Plants: Ideal for supplying compressed air for tools, machinery, and other production equipment in various manufacturing settings.

- Automotive Industry: Ensures reliable and consistent air pressure for assembly lines, pneumatic tools, and automation systems.

- Food & Beverage: Provides clean, dry compressed air for food packaging, processing, and conveying applications, adhering to industry standards for air quality.

- Textile and Paper Mills: Powers machinery and production lines that require continuous, efficient airflow to ensure high productivity.

- Pharmaceuticals: Offers oil-free, clean air for packaging, process control, and other sensitive applications in the pharmaceutical industry.

Why Choose Atlas Copco GA 75?

- Energy Savings: With its highly efficient motor and optimized design, the GA 75 provides significant energy savings, reducing your overall operational costs.

- Reliability & Durability: The GA 75 is built to last, providing consistent, high-quality compressed air even in demanding industrial environments.

- Ease of Use: The Elektronikon® Mk5 controller makes it easy to monitor and manage compressor performance remotely. It also helps you optimize air usage and reduce wastage.

- Minimal Downtime: Thanks to its advanced design and low-maintenance features, the GA 75 minimizes the need for repairs, keeping your operations running smoothly and reducing downtime.

- Sustainability: The GA 75 is engineered with sustainability in mind, offering reduced energy consumption and minimal environmental impact.

Customizable Solutions for Your Business

At Atlas Copco, we understand that each business has unique needs. That’s why we offer customizable solutions with the GA 75, allowing you to tailor the compressor’s specifications to meet the exact requirements of your operations. Our team of experts is ready to assist you with installation, integration, and ongoing support to ensure you get the most out of your investment.

Contact Us

Our team is available to assist you with product details, technical support, and personalized solutions tailored to your specific industry.

| 9829174100 | AFTERCOOLER | 9829-1741-00 |

| 9829174000 | COOLER-OIL | 9829-1740-00 |

| 9829115302 | VALVE-THROTTLE | 9829-1153-02 |

| 9829115300 | VALVE-PLATE THROTTLE | 9829-1153-00 |

| 9829109500 | AFTERCOOLER | 9829-1095-00 |

| 9829109400 | COOLER-OIL | 9829-1094-00 |

| 9829105500 | NUT | 9829-1055-00 |

| 9829105400 | SCREW | 9829-1054-00 |

| 9829105200 | PIPE-TUBE | 9829-1052-00 |

| 9829105100 | PIPE-TUBE | 9829-1051-00 |

| 9829102700 | GEARWHEEL | 9829-1027-00 |

| 9829102600 | GEARWHEEL | 9829-1026-00 |

| 9829102500 | GEARWHEEL | 9829-1025-00 |

| 9829102400 | GEARWHEEL | 9829-1024-00 |

| 9829102206 | COUPLING-HALF | 9829-1022-06 |

| 9829102205 | COUPLING-HALF | 9829-1022-05 |

| 9829102204 | COUPLING-HALF | 9829-1022-04 |

| 9829102203 | COUPLING-HALF | 9829-1022-03 |

| 9829102202 | ELEMENT-COUPLING | 9829-1022-02 |

| 9829102201 | COUPLING-HALF | 9829-1022-01 |

| 9829048700 | REDUCER | 9829-0487-00 |

| 9829047800 | GEAR | 9829-0478-00 |

| 9829029601 | VALVE | 9829-0296-01 |

| 9829029502 | RING-ECCENTRIC | 9829-0295-02 |

| 9829029501 | RING-ECCENTRIC | 9829-0295-01 |

| 9829016401 | GEAR | 9829-0164-01 |

| 9829016002 | GEAR | 9829-0160-02 |

| 9829016001 | WHEEL | 9829-0160-01 |

| 9829013001 | PLATE-END | 9829-0130-01 |

| 9828440071 | C40 T.SWITCH REPLACI | 9828-4400-71 |

| 9828025533 | DIAGRAM-SERV | 9828-0255-33 |

| 9827507300 | SERV.DIAGRAM | 9827-5073-00 |

| 9823079917 | DISK-FLOPPY | 9823-0799-17 |

| 9823079916 | DISK-FLOPPY | 9823-0799-16 |

| 9823079915 | DISK-FLOPPY | 9823-0799-15 |

| 9823079914 | DISK-FLOPPY | 9823-0799-14 |

| 9823079913 | DISK-FLOPPY | 9823-0799-13 |

| 9823079912 | DISK-FLOPPY | 9823-0799-12 |

| 9823079907 | DISK-FLOPPY | 9823-0799-07 |

| 9823079906 | DISK-FLOPPY | 9823-0799-06 |

| 9823079905 | DISK-FLOPPY | 9823-0799-05 |

| 9823079904 | DISK-FLOPPY | 9823-0799-04 |

| 9823079903 | DISK-FLOPPY | 9823-0799-03 |

| 9823079902 | DISK-FLOPPY | 9823-0799-02 |

| 9823075000 | DRAINS | 9823-0750-00 |

| 9823059067 | DISK-FLOPPY | 9823-0590-67 |

| 9823059066 | DISK-FLOPPY | 9823-0590-66 |

| 9823059065 | DISK-FLOPPY | 9823-0590-65 |

| 9823059064 | DISK-FLOPPY | 9823-0590-64 |

| 9823059063 | DISK-FLOPPY | 9823-0590-63 |